3

Feb

When working with concrete flooring, we almost always find ourselves using concrete polishing diamond pads. These amazing pads are capable of working wonders on some of the dirtiest and most damaged floors. That is why we'd like to give you a quick rundown of why these diamond pads should be added to your prep work.

The diamond pad uses the diamonds that are impregnated into it to pull away dirt and debris quickly and efficiently. You can start by using a lot of water with your diamond pad, as these pads work great when wet or dry. If you have harder stains to pull up then our Super Blue or Citra Pro products can be added to the diamond pad for a cleaning you won't believe. After slowly running the grinder (or whatever machine you choose to use) across the floor, squeegee the excess water from the floor and use a shop vac to get rid of it. You do not want the dirty water drying on your newly cleaned concrete.

The diamond pad uses the diamonds that are impregnated into it to pull away dirt and debris quickly and efficiently. You can start by using a lot of water with your diamond pad, as these pads work great when wet or dry. If you have harder stains to pull up then our Super Blue or Citra Pro products can be added to the diamond pad for a cleaning you won't believe. After slowly running the grinder (or whatever machine you choose to use) across the floor, squeegee the excess water from the floor and use a shop vac to get rid of it. You do not want the dirty water drying on your newly cleaned concrete.

While prepping or polishing a floor, you're going to want to begin with a lower grit. One of the lowest grit we offer is 50. So, you will want to go over the floor with a 50 grit pad twice. Then, you move up to a 100 grit pad. You continue this process until you get up to 400 grit. This helps to make many divets in the floor, which will ensure the concrete looks incredible when you're finished working.

While prepping or polishing a floor, you're going to want to begin with a lower grit. One of the lowest grit we offer is 50. So, you will want to go over the floor with a 50 grit pad twice. Then, you move up to a 100 grit pad. You continue this process until you get up to 400 grit. This helps to make many divets in the floor, which will ensure the concrete looks incredible when you're finished working.

The first pad is the Concrete DNA™ Diamond Satellite Pad. These are professional grade diamond impregnated pads that can work well when dry or wet. They are available in 14″, 16″, 17″, 20″ and 27″ diameters and range from 30-1500 grits. This polishing pad is unique in the fact that it has a diamond resin material blown onto both sides of the pad. It also has diamond dots (satellites) that allow for a superior flat cut that no other pad can achieve.

The first pad is the Concrete DNA™ Diamond Satellite Pad. These are professional grade diamond impregnated pads that can work well when dry or wet. They are available in 14″, 16″, 17″, 20″ and 27″ diameters and range from 30-1500 grits. This polishing pad is unique in the fact that it has a diamond resin material blown onto both sides of the pad. It also has diamond dots (satellites) that allow for a superior flat cut that no other pad can achieve.

The Concrete DNA™ Double Sided Diamond Pad is one of the toughest and most efficient pads on the market. This pad is great for polishing some of the roughest floors, but it also great for many other projects too, like burnishing or cleaning. These pads are diamond-encrusted on both sides. Thus you can flip the pad over to utilize the other side too. These pads feature 13", 17", 20", 27" diameter and 200, 400, 800, 1500, and 3000 grits. With such a range in grit availability, customers will be able to tackle almost any polishing job with this simple and fairly priced pad.

The Concrete DNA™ Double Sided Diamond Pad is one of the toughest and most efficient pads on the market. This pad is great for polishing some of the roughest floors, but it also great for many other projects too, like burnishing or cleaning. These pads are diamond-encrusted on both sides. Thus you can flip the pad over to utilize the other side too. These pads feature 13", 17", 20", 27" diameter and 200, 400, 800, 1500, and 3000 grits. With such a range in grit availability, customers will be able to tackle almost any polishing job with this simple and fairly priced pad.

When you choose your pad and you're ready to work, simply tilt the machine upward so you can expose the bottom. You will either find a head with small teeth or a brush on the bottom. All you have to do is simply place the pad onto this head and then put it back in the go position. If you do have problems, then place the pad on the floor and put the machine over. It's really as simple as that.

After using our concrete polishing diamond pads a couple of times, you should feel confident with them. They're incredibly easy to utilize and can really transform the final result of a project. Plus, they do make working on tough jobs a bit easier.

For more on our products, check us out on Instagram.

When you choose your pad and you're ready to work, simply tilt the machine upward so you can expose the bottom. You will either find a head with small teeth or a brush on the bottom. All you have to do is simply place the pad onto this head and then put it back in the go position. If you do have problems, then place the pad on the floor and put the machine over. It's really as simple as that.

After using our concrete polishing diamond pads a couple of times, you should feel confident with them. They're incredibly easy to utilize and can really transform the final result of a project. Plus, they do make working on tough jobs a bit easier.

For more on our products, check us out on Instagram.

Diamond pads for cleaning:

Diamond pads are one of the best things you can use to clean up some of the dirtiest floors around. When you get an old concrete floor that has been used for years with very little maintenance, you're going to have dirt and grime pretty much embedded in the flooring. On top of that, you might also be dealing with grease, chemicals, and who knows what else. The diamond pad uses the diamonds that are impregnated into it to pull away dirt and debris quickly and efficiently. You can start by using a lot of water with your diamond pad, as these pads work great when wet or dry. If you have harder stains to pull up then our Super Blue or Citra Pro products can be added to the diamond pad for a cleaning you won't believe. After slowly running the grinder (or whatever machine you choose to use) across the floor, squeegee the excess water from the floor and use a shop vac to get rid of it. You do not want the dirty water drying on your newly cleaned concrete.

The diamond pad uses the diamonds that are impregnated into it to pull away dirt and debris quickly and efficiently. You can start by using a lot of water with your diamond pad, as these pads work great when wet or dry. If you have harder stains to pull up then our Super Blue or Citra Pro products can be added to the diamond pad for a cleaning you won't believe. After slowly running the grinder (or whatever machine you choose to use) across the floor, squeegee the excess water from the floor and use a shop vac to get rid of it. You do not want the dirty water drying on your newly cleaned concrete.

Concrete Polishing Pads for Prep Work or Polishing:

No matter what project you're working on, you're going to need to prep your concrete floors. When you use a diamond pad, you're giving your floor a better chance of pulling in the product you're using so the finish will last longer and have a better overall finish. When you look at concrete, you might not realize that there are lots of pores. The role of the concrete polishing diamond pads is to help scratch the surface of the concrete, thus creating divets that will allow light to bounce off of the surface. These divets will take in the product that you're applying to the floor so that it sticks longer, but also so that it creates a polished finish because it is reflecting light in a more appropriate manner instead of all over the place. While prepping or polishing a floor, you're going to want to begin with a lower grit. One of the lowest grit we offer is 50. So, you will want to go over the floor with a 50 grit pad twice. Then, you move up to a 100 grit pad. You continue this process until you get up to 400 grit. This helps to make many divets in the floor, which will ensure the concrete looks incredible when you're finished working.

While prepping or polishing a floor, you're going to want to begin with a lower grit. One of the lowest grit we offer is 50. So, you will want to go over the floor with a 50 grit pad twice. Then, you move up to a 100 grit pad. You continue this process until you get up to 400 grit. This helps to make many divets in the floor, which will ensure the concrete looks incredible when you're finished working.

Types of diamond pads that we offer:

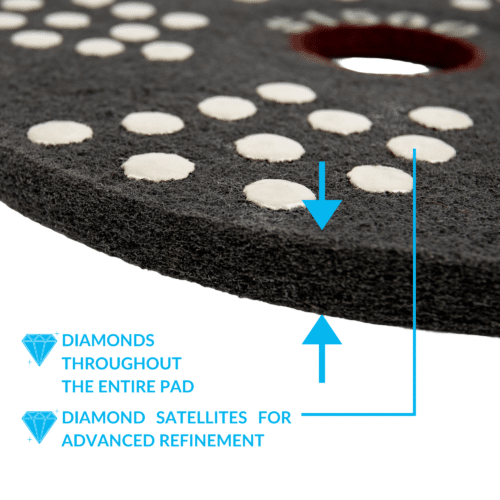

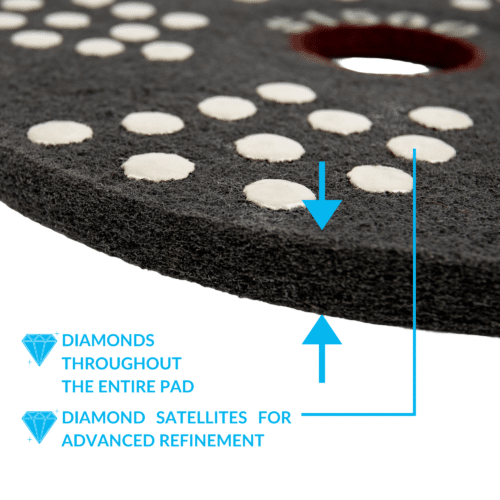

Concrete DNA™ Diamond Satellite Pads:

The first pad is the Concrete DNA™ Diamond Satellite Pad. These are professional grade diamond impregnated pads that can work well when dry or wet. They are available in 14″, 16″, 17″, 20″ and 27″ diameters and range from 30-1500 grits. This polishing pad is unique in the fact that it has a diamond resin material blown onto both sides of the pad. It also has diamond dots (satellites) that allow for a superior flat cut that no other pad can achieve.

The first pad is the Concrete DNA™ Diamond Satellite Pad. These are professional grade diamond impregnated pads that can work well when dry or wet. They are available in 14″, 16″, 17″, 20″ and 27″ diameters and range from 30-1500 grits. This polishing pad is unique in the fact that it has a diamond resin material blown onto both sides of the pad. It also has diamond dots (satellites) that allow for a superior flat cut that no other pad can achieve.

Concrete DNA™ Double Sided Diamond Pads:

The Concrete DNA™ Double Sided Diamond Pad is one of the toughest and most efficient pads on the market. This pad is great for polishing some of the roughest floors, but it also great for many other projects too, like burnishing or cleaning. These pads are diamond-encrusted on both sides. Thus you can flip the pad over to utilize the other side too. These pads feature 13", 17", 20", 27" diameter and 200, 400, 800, 1500, and 3000 grits. With such a range in grit availability, customers will be able to tackle almost any polishing job with this simple and fairly priced pad.

The Concrete DNA™ Double Sided Diamond Pad is one of the toughest and most efficient pads on the market. This pad is great for polishing some of the roughest floors, but it also great for many other projects too, like burnishing or cleaning. These pads are diamond-encrusted on both sides. Thus you can flip the pad over to utilize the other side too. These pads feature 13", 17", 20", 27" diameter and 200, 400, 800, 1500, and 3000 grits. With such a range in grit availability, customers will be able to tackle almost any polishing job with this simple and fairly priced pad.

How to install a diamond pad:

One of the most common ways to use a diamond pad is on a low-speed buffer. We actually have these for sale or rent, but you can find them in many hardware, home improvement, and other retail stores. This machine runs at about 175 to 300 RPMs. They also typically hold a 15" or 17" pad. When you choose your pad and you're ready to work, simply tilt the machine upward so you can expose the bottom. You will either find a head with small teeth or a brush on the bottom. All you have to do is simply place the pad onto this head and then put it back in the go position. If you do have problems, then place the pad on the floor and put the machine over. It's really as simple as that.

After using our concrete polishing diamond pads a couple of times, you should feel confident with them. They're incredibly easy to utilize and can really transform the final result of a project. Plus, they do make working on tough jobs a bit easier.

For more on our products, check us out on Instagram.

When you choose your pad and you're ready to work, simply tilt the machine upward so you can expose the bottom. You will either find a head with small teeth or a brush on the bottom. All you have to do is simply place the pad onto this head and then put it back in the go position. If you do have problems, then place the pad on the floor and put the machine over. It's really as simple as that.

After using our concrete polishing diamond pads a couple of times, you should feel confident with them. They're incredibly easy to utilize and can really transform the final result of a project. Plus, they do make working on tough jobs a bit easier.

For more on our products, check us out on Instagram.